Development: May 2022 – July 2022.

Works performed:

Hardware and software main specifications:

The automated process control system has a three-level structure:

The structure is implemented as a three-level hierarchical system.

The system includes the following operator workstations: Operator workstation (OS Station 1...6);

Project description:

The project involves complete replacement of the existing automated process control system of the atmospheric distillation units with integration into the automated process control system of Tomskneftepererabotka LLC.

Works performed:

- Inspection of the facility, collection of initial data

- Project development including development of detail design documentation

- Development of application software for PLC and SCADA

Hardware and software main specifications:

The automated process control system has a three-level structure:

The structure is implemented as a three-level hierarchical system.

- The upper level is a human-machine interface.

The system includes the following operator workstations: Operator workstation (OS Station 1...6);

- The middle level is implemented on the basis of Simatic S7 CPU-410-5H programmable logic controllers and a set of SIMATIC ET200M subsystem I/O devices.

- The lower level (field level) includes sensors, secondary measuring transducers, actuators, etc.

Project description:

The project involves complete replacement of the existing automated process control system of the atmospheric distillation units with integration into the automated process control system of Tomskneftepererabotka LLC.

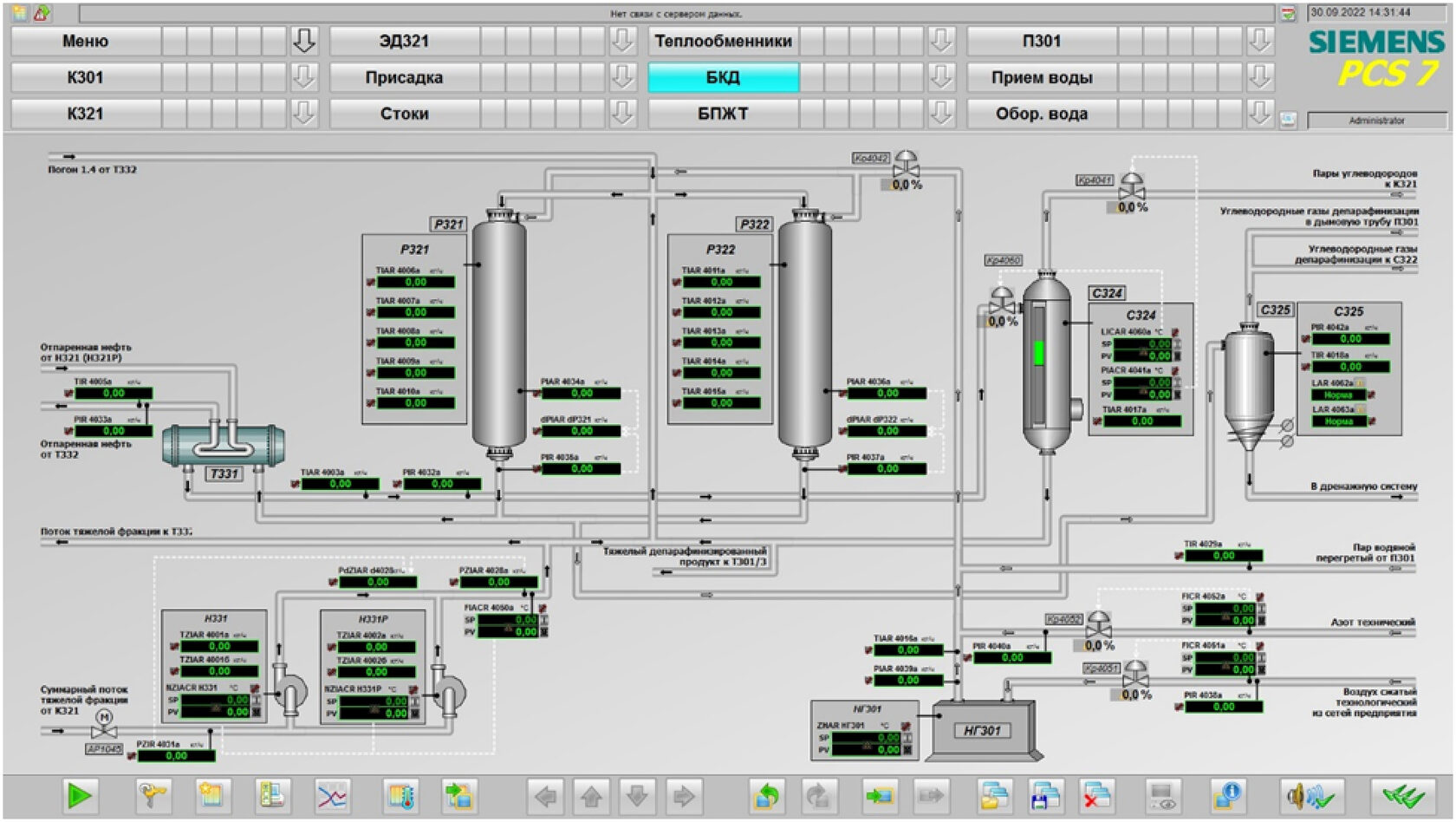

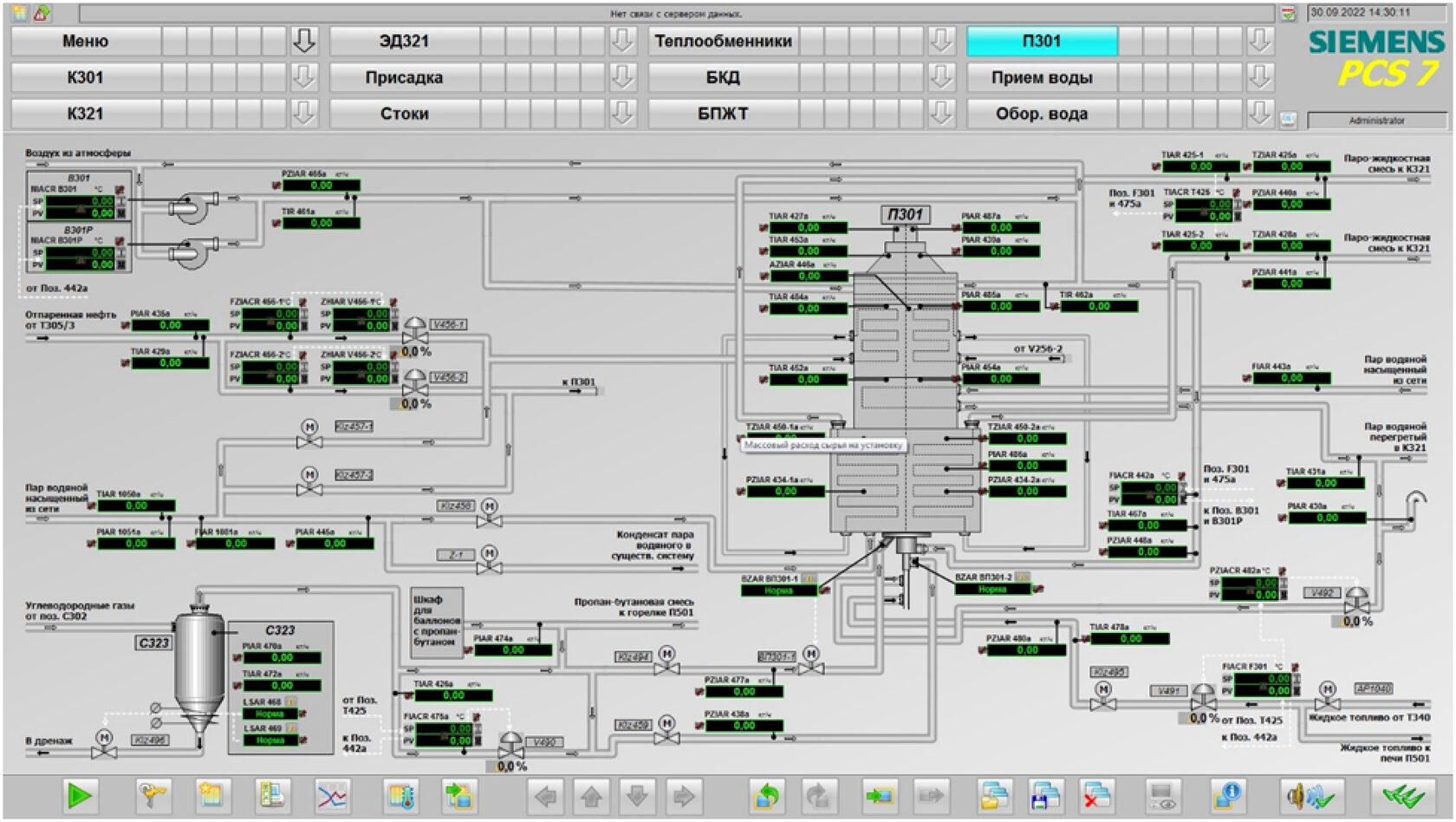

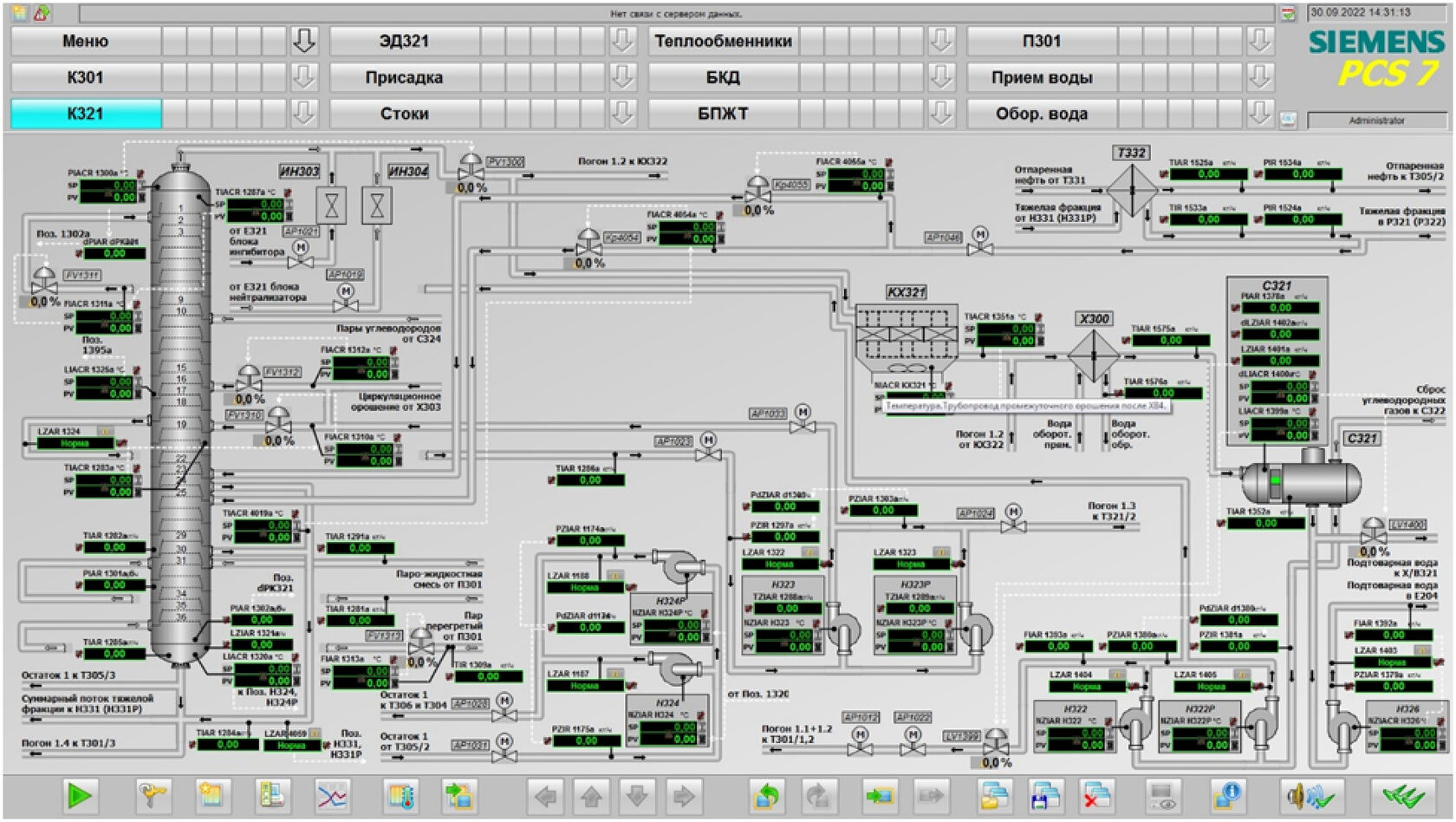

Mimic diagrams:

Heater P301

Column K321

Hydrogen-free catalytic dewaxing section