Development: September 2022 – November 2022

Implementation: June 2023

Facility description:

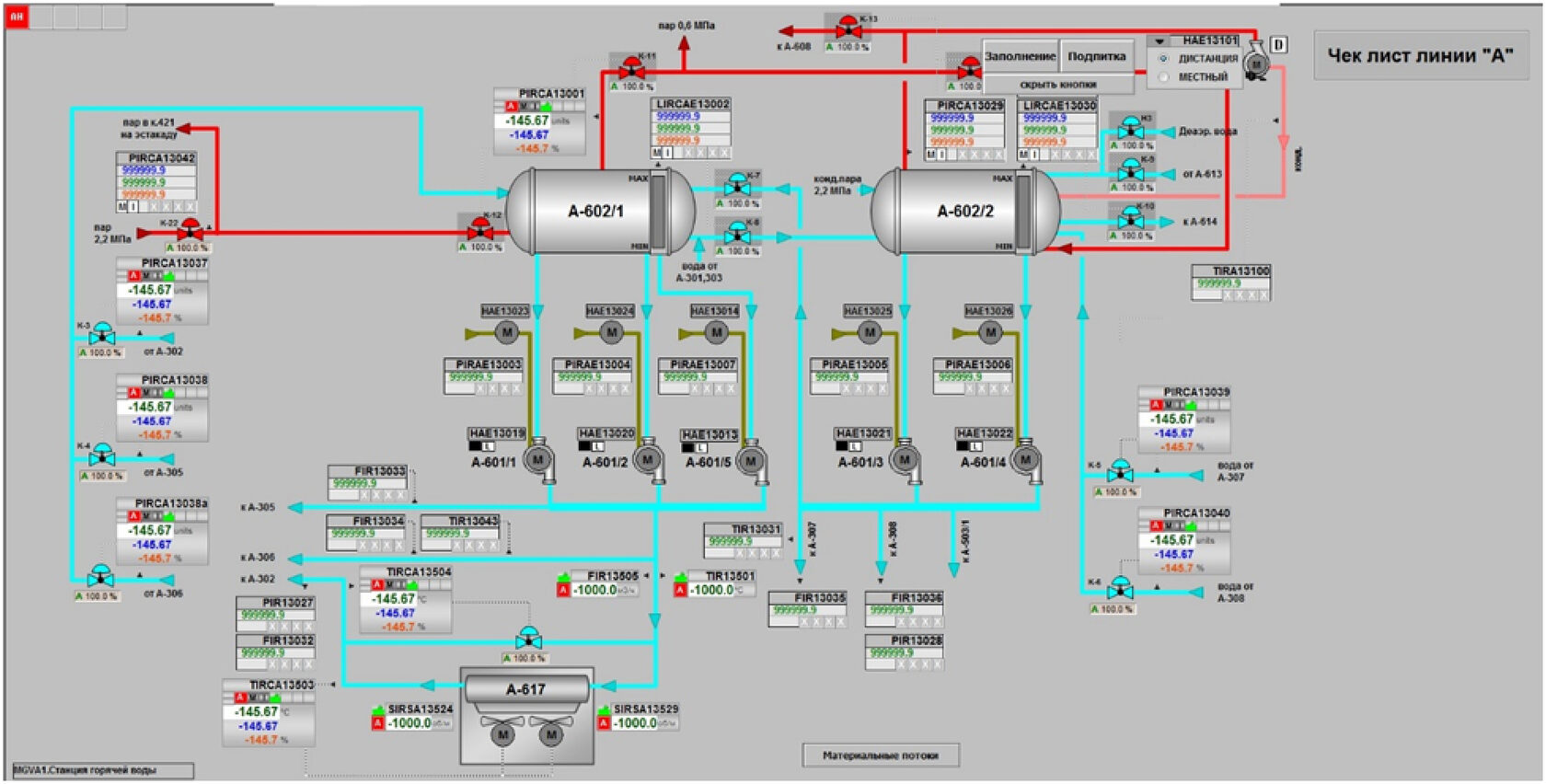

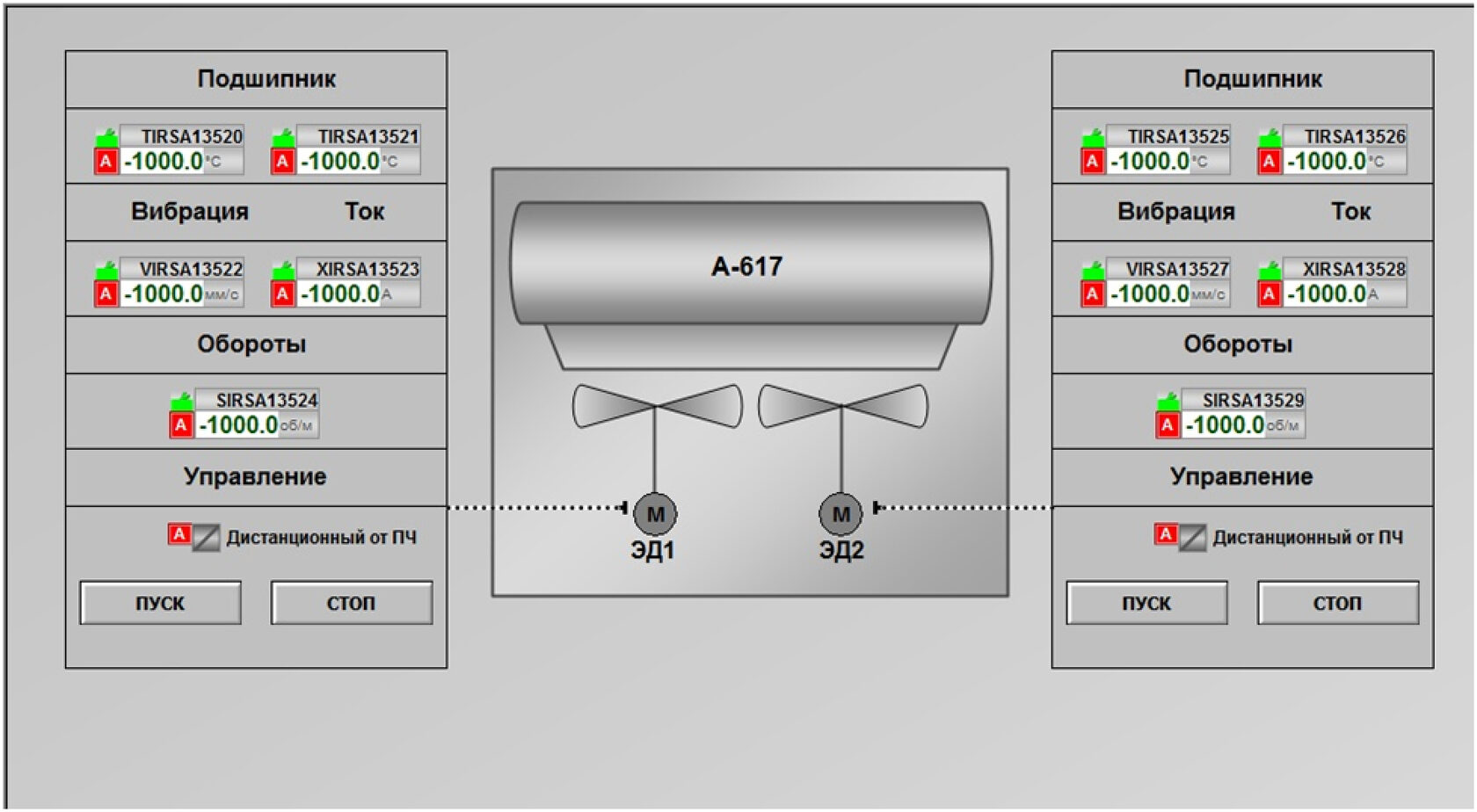

A hot water air cooling unit control system for a first zone of the ethylene polymerization reactor. Integration into the existing APCS.

Works performed:

Hardware and software main specifications:

Project features:

— Works at a hazardous production facility were performed while the existing equipment was in operation.

— Integration of the existing APCS based on the SIEMENS controllers with a new air cooling unit control subsystem.

— Precise process control with the use of frequency converters.

— Data transmission to the enterprise’s MES.

Implementation: June 2023

Facility description:

A hot water air cooling unit control system for a first zone of the ethylene polymerization reactor. Integration into the existing APCS.

Works performed:

- Inspection of the facility, collection of initial data

- Development of design and detail design documentation for the APCS according to the requirements specifications

- Development of application software for PLC and SCADA

- Installation, start-up and adjustment

- Personnel training on the system operation

- Putting into trial operation

- Elimination of identified deficiencies

- Putting into commercial operation

Hardware and software main specifications:

- Upper level: SCADA system WinCC

- Lower level: ABAK-K2 and SIMATIC S7-417H controllers.

- Industrial Ethernet field bus.

- Data exchange with a local control system via Modbus RTU protocol.

Project features:

— Works at a hazardous production facility were performed while the existing equipment was in operation.

— Integration of the existing APCS based on the SIEMENS controllers with a new air cooling unit control subsystem.

— Precise process control with the use of frequency converters.

— Data transmission to the enterprise’s MES.